Image-based rheology

Concrete is one of the most widely used building materials in the construction industry; in Germany alone, the production volume of ready-mixed concrete was over 50 million m3 in 2020. In order to conserve natural resources, demolition material (concrete, masonry, rock) from the deconstruction of buildings can be reused in concrete production in the form of recycled aggregates. In today's construction industry, however, mineral resources tend to be downcycled rather than recycled, even though the construction sector was responsible for more than 55% of Germany's total waste generation in 2019, according to the German Federal Statistical Office. One of the reasons is the fact that the properties of the demolition materials to be recycled vary widely and can negatively influence the new concrete to an unknown extent - here in particular the fresh concrete properties (workability, tendency to segregate). To overcome this problem, more cement can be used in the concrete mixing process when working with recycled aggregates to compensate for these fluctuations. However, this solution is neither ecologically nor economically justifiable, as large amounts of CO2 are released during the production of cement. If the properties of the freshly mixed concrete could already be determined during the mixing process, it would be possible to compensate for the unknown negative effects resulting mainly from the use of recycled materials and from fluctuations in the mixing process, e.g. by using suitable additives.

The aim is to observe the concrete mixing process with optical sensors and to directly determine the properties of the concrete from the image data. Since working with fresh concrete always involves a lot of effort and the time in which the fresh concrete can be worked with before it hardens is limited, tests were first carried out with coloured ultrasonic gel, a substitute that is a frequently used reference substance for cement paste. The ultrasonic gel was mixed to varying degrees with water to obtain different consistencies. Additionally, clay granules were added to simulate the aggregate in the concrete. The use of ultrasonic gel allowed further tests to be carried out, testing different camera and lighting positions.

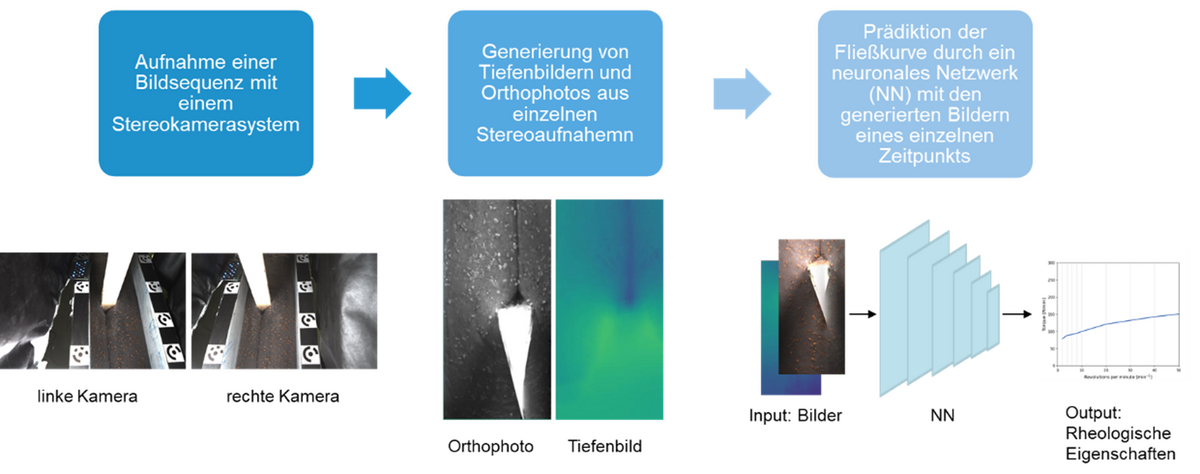

The different ultrasonic gels were added one after the other to a linear mixing system and set in motion with a mixing paddle. A stereo camera system records this process and allows a 3D reconstruction of the surface of the ultrasonic gels. A learning procedure was developed that uses a digital elevation model (DEM) and an orthophoto (generated by classical photogrammetric methods) to predict the rheological properties. A regression is performed by a Convolutional Neural Network (CNN) which outputs certain values describing the rheological properties. It was shown that it is possible to extract properties from images of a concrete substitute. The next steps include testing the methodology on real concrete.