Image-based Granulometry

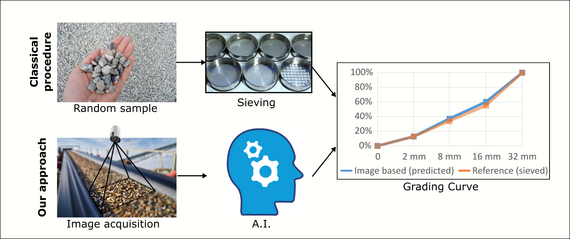

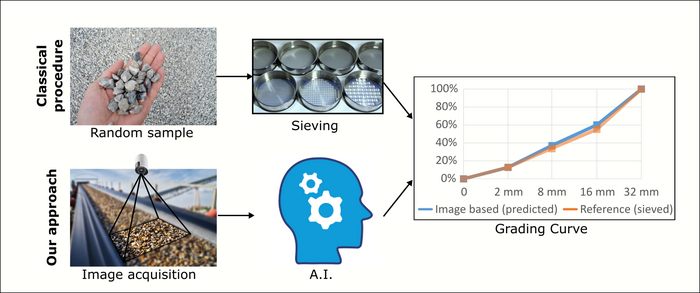

With up to 80 % of volume, a large component of concrete consists of fine and coarse aggregate particles (normally with mean diameters between 0.125 and 32 mm) which are dispersed in the cement paste matrix. As an essential constituent of concrete, the aggregate’s characteristics such as type, density, particle shape and particle size distribution have a substantial effect on the properties of the fresh and hardened concrete. In practice, the grading curve of the aggregates is usually determined from small random batch-samples using mechanical sieving (cf. top of the Figure), thus extrapolating from a sample of a few kilograms to many tons of aggregates. As a consequence, the unknown variations of the aggregate’s grading curve (especially pronounced in the case of recycled materials), is not properly taken into account in the mix design. Further, variations in the particle shape and composition of the aggregates (e.g. fractions of brick rubble in recycled aggregates) remain undetected. In order to still adhere to the concrete’s quality requirements, these variations are usually compensated for by a distinct increase of the cement content, which, however, is neither economically nor ecologically justifiable.

A key to economically and ecologically optimized concrete compositions and to increasing the use of recycled materials lies in the development of technologies that make it possible to continuously record the fluctuations of the starting materials and to control their influences on the end product.

Towards the goal of deriving precise knowledge about the actual particle size distribution of the aggregate, thus eliminating the unknown variations in the material’s properties, an approach for the image based prediction of the size distribution of concrete aggregates (cf. bottom of the Figure) is developed within the research project ReCyCONtrol. Incorporating such an approach into the production chain of concrete enables to react on detected variations in the size distribution of the aggregate in real-time by adapting the composition, i.e. the mixture design of the concrete accordingly, so that the desired concrete properties are reached.